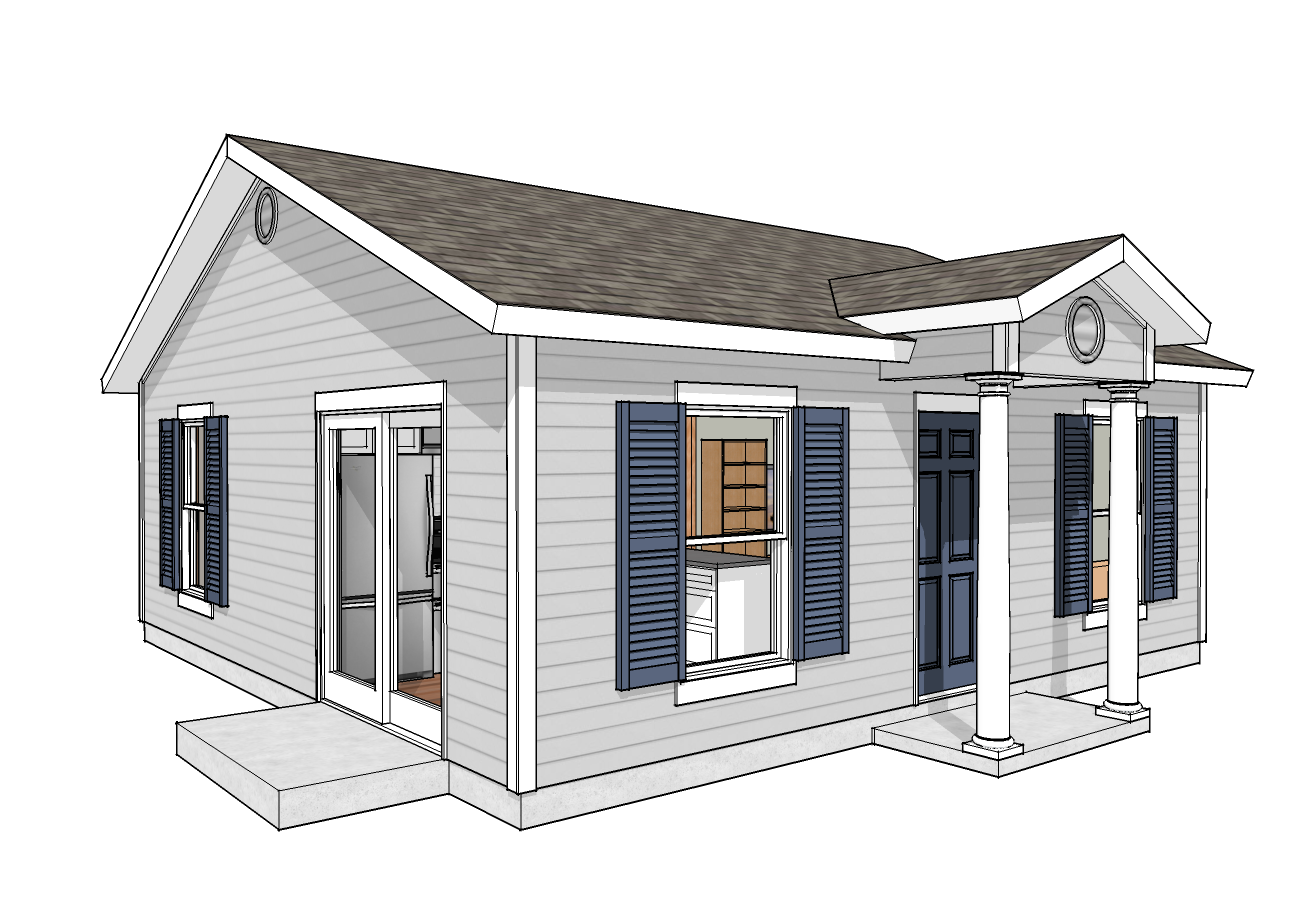

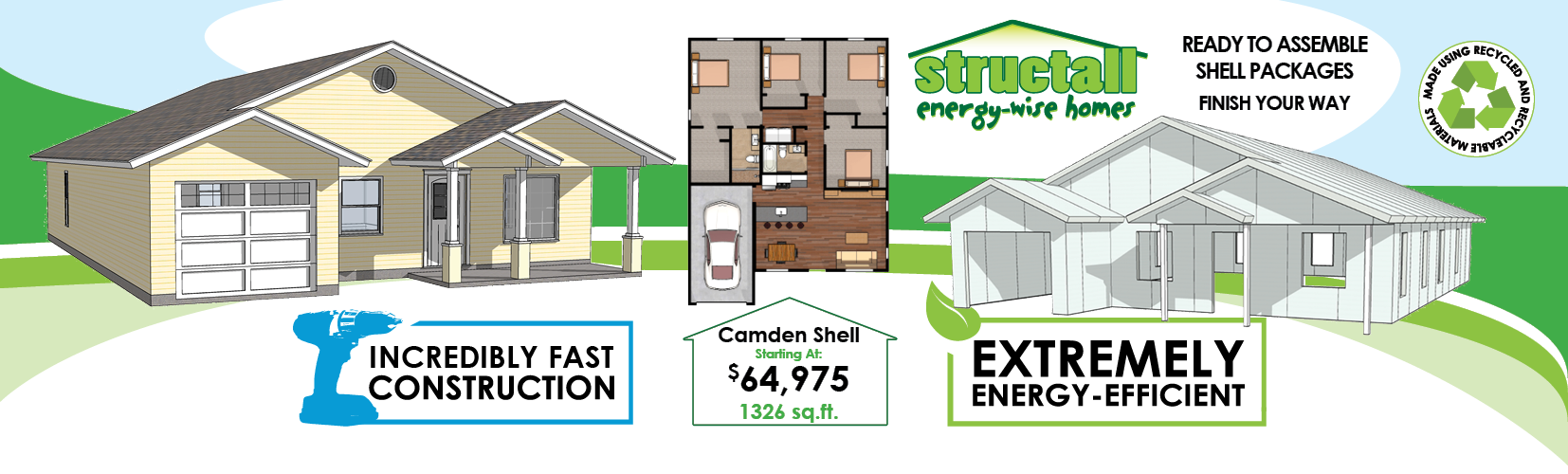

Snap-N-Lock™ Structural Insulated Panel

SIP's are high-performance composite/sandwich panels for roofs, walls and floors in residential and commercial construction.

- Combines framing, insulation, and sheathing for exceptionally short construction time.

- More energy-efficient than conventional construction.

- Structall offers panels for both habitable structures and patio applications.

Why choose Snap-N-Lock Structural Insulated Panels?

Save Time

Our easy snap in place Snap-N-Lock Structural Insulated Panels save time in construction.

Save Money

Save money on building time costs and energy bills with our durable energy efficient products.

Save Energy

Save energy and help reduce emissions with better insulation and ventilation.

Recognitions & Approvals

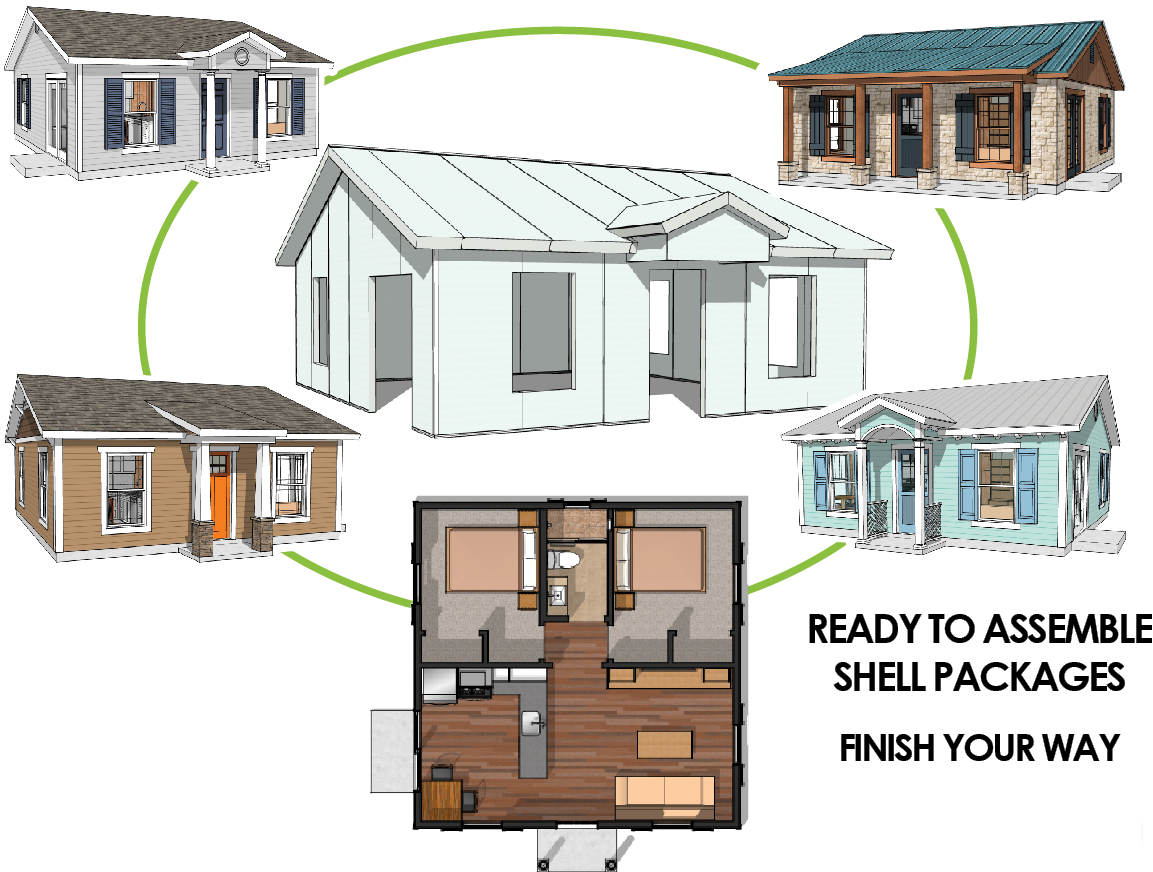

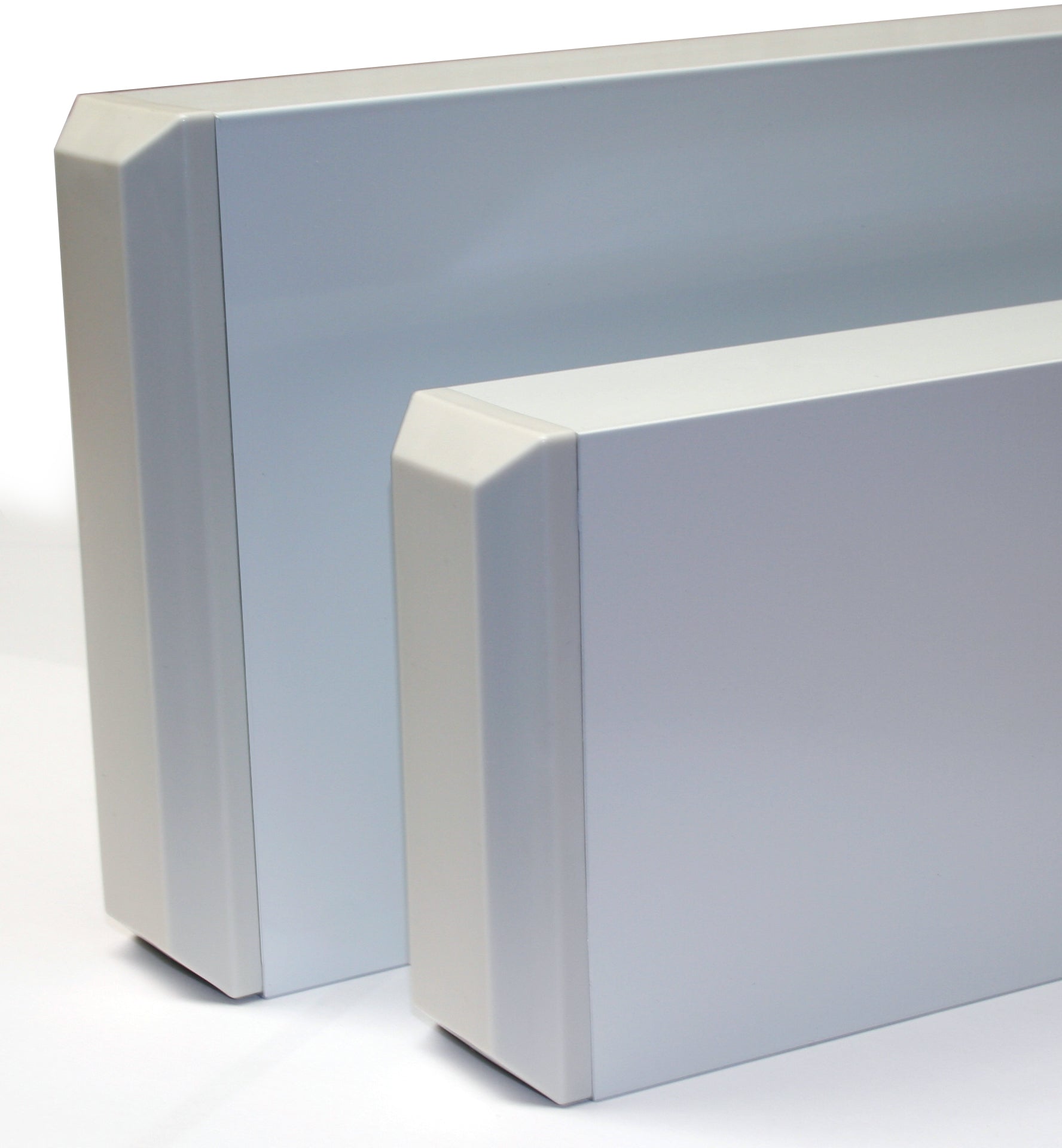

Build Your Next Home or Garage: Steel-Skinned Snap-N-Lock Structural Insulated Panels

FBC & ICC-ES (CBC/CRC) Recognized for Construction of Habitable Structures.

We're a One-Stop Shop for Your Next Project

SIP's and MORE

Not only do we manufacture SIPs, we also distribute a vast array of products selected to best support a SIP-based project.